Process

The Process Flow:

- Unloading (or) De-Stuffing of Cargo in Warehouse.

- Cross checking the Invoice as per the physical stock mentioned.

- Checking the materials for any Damage, Mis-Match, Excess or Shortage Etc. (IR – Raising)

- Stacking the material as per the Staking Norms (RACKING / NON-RACKING)

- Storing 20 Days production coverage Stocks in our warehouse

- Same time filling 3 Days Production Coverage at In-plant.

- As per Daily Indent, we are picking the Material in FIFO Basis and sending the goods in our Transportation in on time to the production line.

- Weekly inventory monitoring.

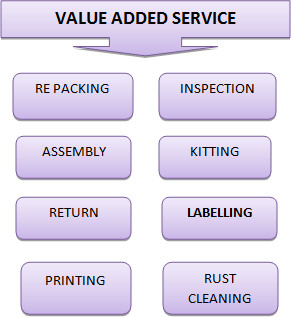

- Rust Cleaning the Parts (as per the Customer Need – VAS)

- Prompting on Specified Stocks about below minimum Stock Level.

| No | Process | Responsiblity |

|---|---|---|

| 1 |

Select random SKUs for stock verification on daily basis and also select value high SKUs on random basis on every day. On account of stock verification can be circulated on every start of month to all concerns. Calculation Total qty of stock = daily count stock + Issue qty. |

Warehouse Executive/Supervisor |

| 2 | Take physical stock count with system stock count and verify the variance in document |

Warehouse Executive/Supervisor |

| 3 | Tally physical stock count with system stock count and verify the variance in document. |

Warehouse Executive/Supervisor |

| 4 | Escalation of Stock count variance to WH In-charge. |

Warehouse Executive/Supervisor |

| 5 |

Reconciliation of stock variance at Warehouse and variance requires adjusting of stock in system need to be escalated and resolved within short period of a week. Note: Kindly ensure proper document for adjustment of stock in system from concerns. |

Warehouse Executive/Supervisor |